The ability to scan through a solid object and see what is inside was once thought to be a technology of the future, but this technology is available to us now. For many years, CT scanning (or Computed Tomography) was only available to use in the medical field, but over the last few years it has been adapted and is now being used in the manufacturing world. This technology is making the life of many manufacturing workers easier and is giving them opportunities to do things they were not able to do before.

The main advantage of CT scanning is that it allows the inspection of an object’s interior without damaging or ruining the object itself.

Industrial CT scanners, used in the manufacturing field, use the same type of technology as scanners seen in hospitals. They take multiple readings from multiple angles and convert them into a 3D image. Once this is done, a specialist can then generate a CAD-to-art comparison map, create a 3D model of the object, or even reverse engineer the object.

Some of the most common uses of CT scanning in metrology include:

Reverse engineering – CT scanning becomes extremely useful when you have a manufactured object, but not the original print or design. It allows you to take measurements of the object and then create an exact CAD replica.

Non-contact measurement – it allows manufacturers to capture the shape of the object through the use of laser emitting 3D scanners.

Contact measurement – this is a method of collecting single points relative to each other. When trying to capture small volume information, articulating arms are used. When the information is larger, optical solutions like laser trackers are used.

Long range scanning – it allows specialists to capture a detailed 360-degree 3D image of a structure or land with high accuracy.

In the manufacturing field these 3D scanners are used for inspection of components and to make sure that a certain object part meets the specifications. By confirming that the object is okay, they can make sure that the mass produced part comes out the same every time.

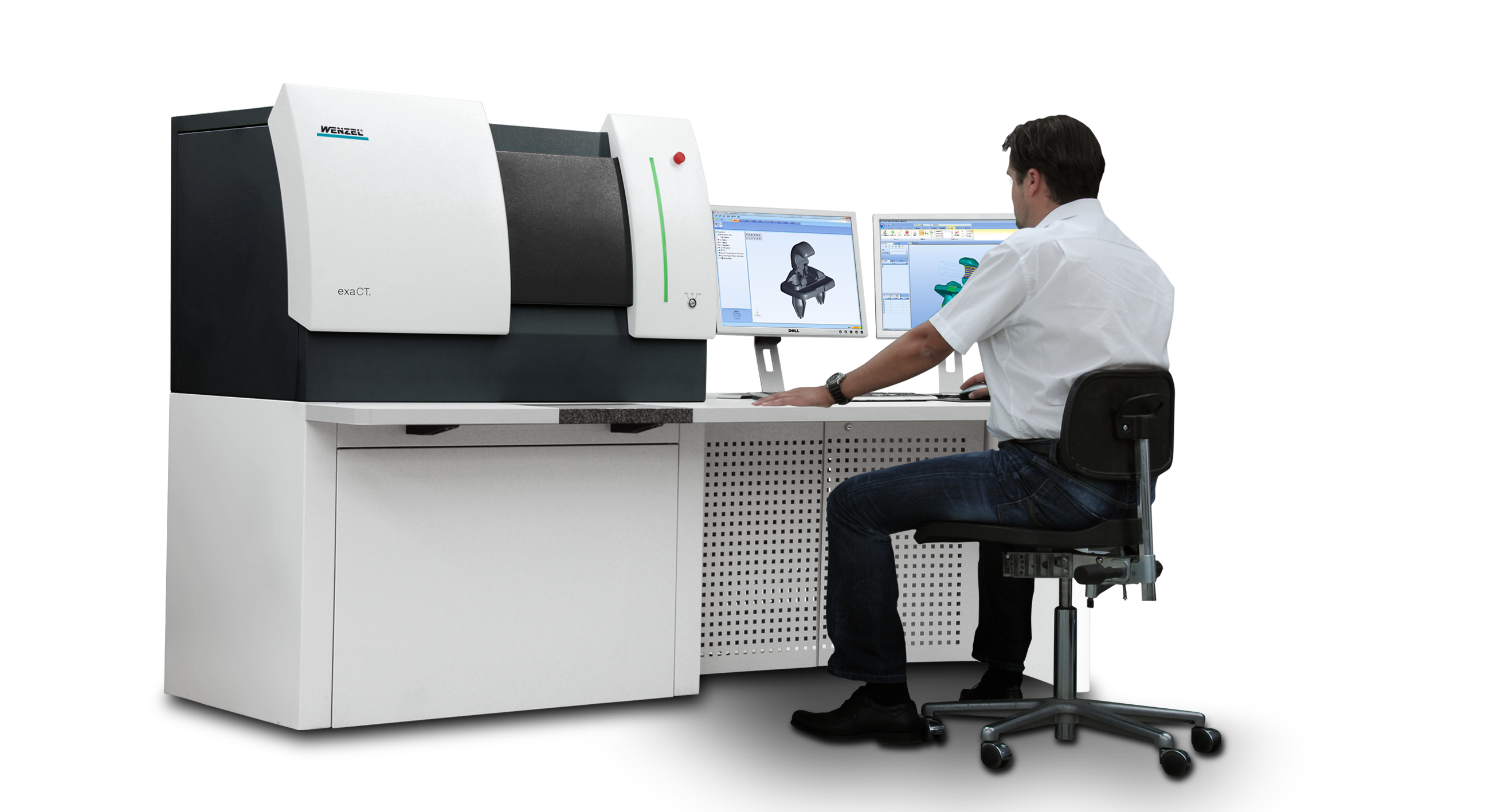

Manchester Metrology is now an official re-seller of the WENZEL exaCT® M, a powerful and flexible CT scanner, used for measuring and testing small to medium-sized components. Its compact design with well thought-out ergonomics make it possible for this CT scanner to combine more power and flexibility with less space requirements. It has an integrated evaluation unit which allows for easy loading and makes it ideal for automating measuring and testing processes.

This workstation is used for measuring and testing small to medium-sized components, with a measuring volume of 300mm in height and 200mm in diameter. It is particularly suitable to use in dimensional metrology and non-destructive testing (NDT) of components, assemblies, and materials.