Laser Scanning & Reverse Engineering

Manchester Metrology offer bespoke 3D scanning services to a wide range of industries across the UK, including aerospace, automotive, construction and more.

Using our non-contact HD laser scanners, we provide CAD comparison services with detailed reports tailored to your requirements. With portable equipment, we can acquire data from any location and environment.

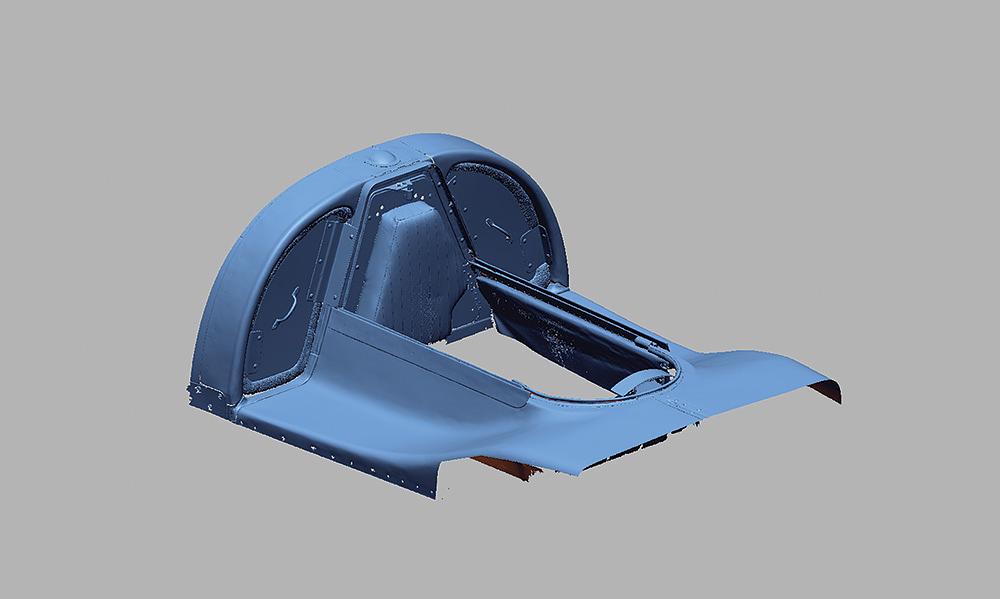

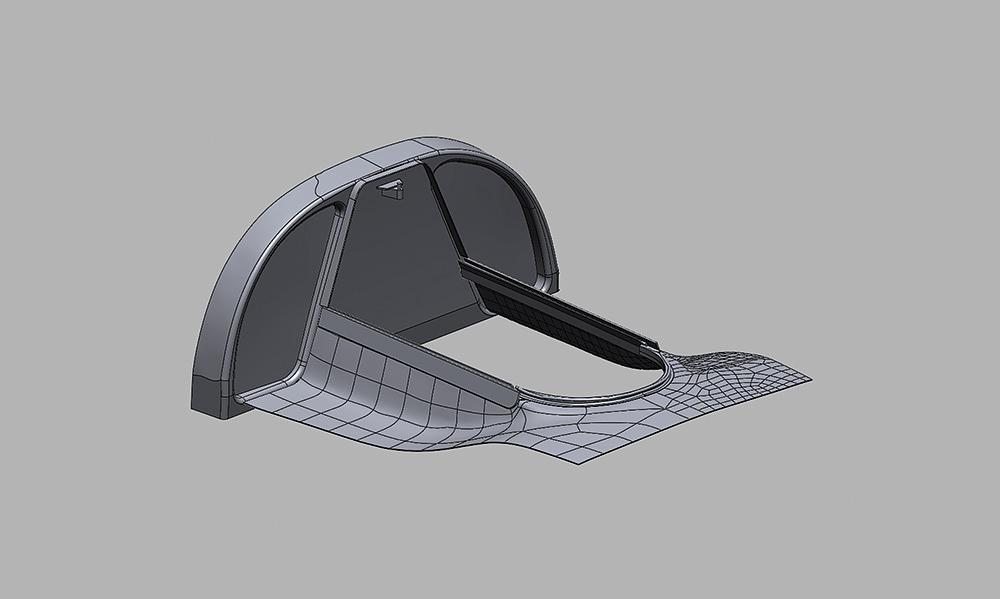

We have extensive experience in reverse engineering, producing true-to-form 3D data in .stl file formats and full parametric CAD models in multiple file formats.

Reverse engineering is the process of extracting design information using 3D scanners and probing to generate 3D models from measured data.

This is particularly useful as manufacturers often have an extensive range of machines and parts. When a part breaks or needs replacing, it is often more cost-effective to replace only the part rather than the entire product. Reverse engineering allows you to recreate a part by understanding its original design.

We offer advanced HD laser scanning and reverse engineering services, using a range of equipment including:

Our advanced technology enables more precise scans in less time, making it ideal for larger-scale projects that require high volumes of scanning and reverse engineering in a reduced time frame.

Contact our team below for more information