Matthew suffers from hemiplegia on the right side of his body, meaning he is partially paralysed on that side. After initially struggling with cycling in his younger years, he mastered the art at 13. Progressing through the Great British Cycling Team’s development programme, Matthew made his world-level debut at the 2019 Track World Championships in Apeldoorn, where he finished 5th in the 1,000m and 12th in the individual pursuit. During the event, he also broke the C2 flying 200m world record at the time. He continued to progress on the track, setting new personal best times in both the 1,000m and individual pursuit at the 2019 UCI Manchester Para-cycling International.

Since this project, Matthew has continued to build on his achievements, including his success at the 2024 UCI Para-Cycling Track World Championships, where he claimed a bronze medal in the men’s C2 omnium.

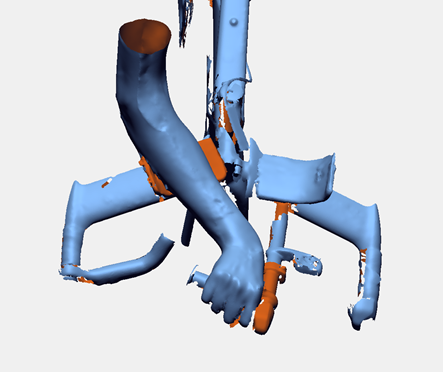

At the time of our project, Matthew had already found a riding position that provided stability and comfort for his hemiplegia. He and his coaches aimed to capture data on that ideal position to build a custom support to fix his arm in place. This initial solution consisted of a support pad at the top of his forearm, one by his wrist and a grip for his hand. The goal was to design something more advanced, potentially manufactured from carbon fibre, to maximise comfort and aerodynamics while maintaining safety and stability.

To begin the process, we first took a quick scan of Matthew’s bike in position. This gave us a basic reference frame for aligning the scan data when combining it later. We then asked Matthew to get into his riding position and we captured two scans of his arm from the shoulder down, including some of the bike in the scan.

In terms of equipment, we used the Hexagon AS1 scanner with a Hexagon Absolute Arm 85 to scan the bike and a 3D scanner to scan Matthew. The AS1 was ideal for the bike’s high-gloss finish, while the 3D scanner’s non-rigid mode minimised the need for extensive post-processing.

Once the scanning was completed, we needed to process the data. Scanning non-rigid objects can be challenging, as it can result in overlapping surfaces and scan distortions. We refined the data, which involved:

– Aligning the scans.

– Trimming the scans in areas.

– Merging the three scans.

– Converting the resulting mesh to a point cloud.

– Applying curvature filters and noise reduction.

– Re-meshing from points.

– Deleting overlapping data and refilling holes.