PMT Inspect

PMT Inspect

Description

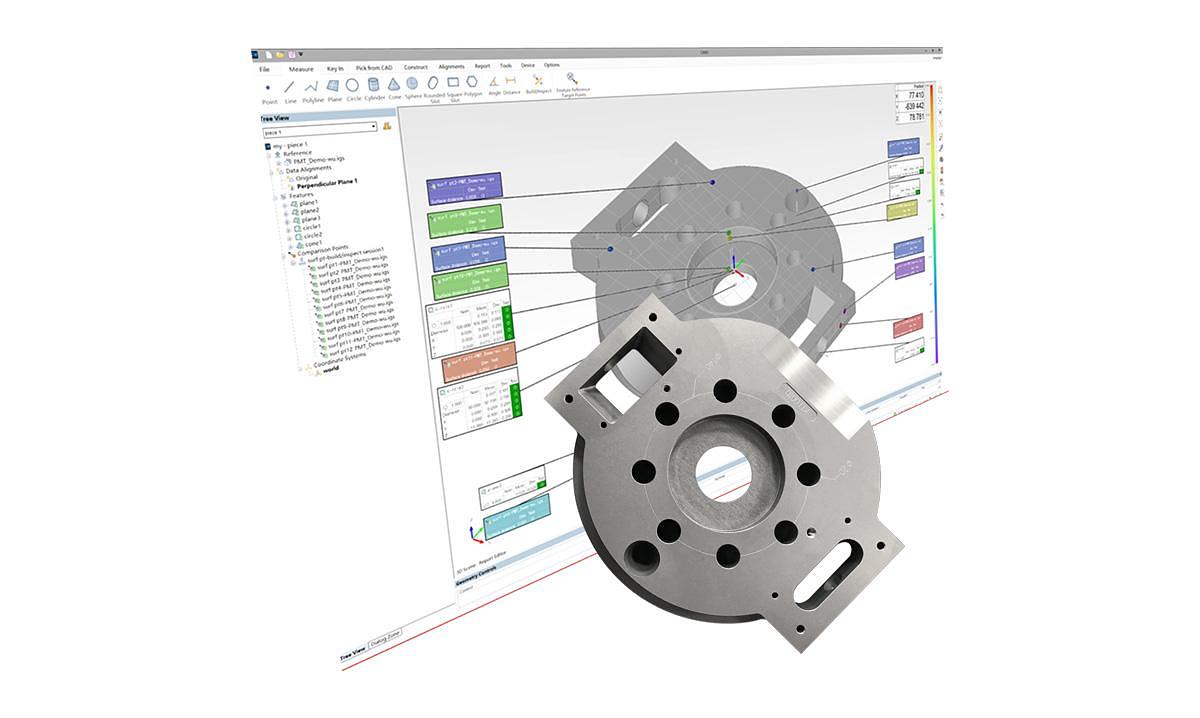

PMT Inspect Software

A platform designed to support multiple application scenarios and meet a wide range of measurement requirements.

PMT Inspect is industrial 3D measurement software developed by PMT Technologies. Designed to operate with portable measuring machines, it enables data capture across manufacturing environments wherever required.

The software serves as a multi-dimensional control system that can help check parts and tooling in various forms, probe into the quality control issues related to the manufacturing and assembly process and execute real-time adjustment for the assurance of good quality of the fitting components.

Technical Features

Virtual Probe

The Virtual Probe enables simulated data acquisition without the use of a physical device. It is suited to applications such as measurement programme planning and accuracy evaluation and supports improved workflow efficiency.

Enhancing Productivity

The Virtual Probe allows users to organise and optimise workflows without connecting a physical device, helping to reduce time and improve overall efficiency.

Reducing Measurement Costs

Simulation mode allows users to reduce errors and avoid repeated measurements, which helps lower inspection costs and improve efficiency.

Improving Work Flexibility

Virtual Probe allows users to perform simulated data acquisition and analysis at any time and in any location, regardless of the availability or working status of a physical device. This provides greater flexibility and convenience when performing measurements and inspection.

Measuring Dimensions and Deviations

PMT Inspect calculates dimensions and deviations to provide measurement results for objects.

• Objects are measured in real time and compared with design drawings to ensure they meet required specifications.

• Quality control and inspection are supported during production.

• Sizes and shapes are measured to identify deviations or defects and help maintain required standards.

Alignment Tools and Coordinate Systems

PMT Inspect provides a variety of alignment tools and flexible methods for creating coordinate systems, allowing users to select the most appropriate for their needs. It meets different measurement application requirements and provides accurate and reliable data.

Build and Inspect

The Build/Inspect mode assists with quick and accurate assembly and verification of parts. It ensures that product standards are met and supports further analysis and decision-making.

Inspecting Multiple Pieces

Users can measure multiple objects at the same time and edit alignments, measurement objects and reports. It provides a guidance-based workflow for inspecting subsequent pieces and allows operators to start measurement without the need for programming or training.

Working with Multiple Device Positions

PMT Inspect includes a powerful function to manage multiple device positions – the leapfrog command. Measured targets are matched automatically and the measuring range can be expanded to support inspection of large workpieces.

Advantages

Reliable Algorithm

PMT Inspect has achieved the internationally recognised PTB certification in metrology.

Automation

Multi-part inspection and quick export of customised reports improve workflow efficiency.

Clear Interface

The simple and uncluttered interface is easy to use, even for new users.

Versatility

Functions such as geometric dimension measurement, GD&T and build/inspect mode meet most industrial application requirements. PMT Inspect is widely used in sectors including construction machinery, automotive, energy, machining and education.

Official PMT UK Reseller

As the official PMT UK reseller, we’re able to provide support to our customers to make sure they get the very best from their equipment. We work hard to understand every aspect of the equipment and software, so we’re always happy to answer any questions you might have.

Specifications

| Manufacturer | PMT |

| Model | Inspect |

| Condition | New |

| Stock Number | 6198878 |